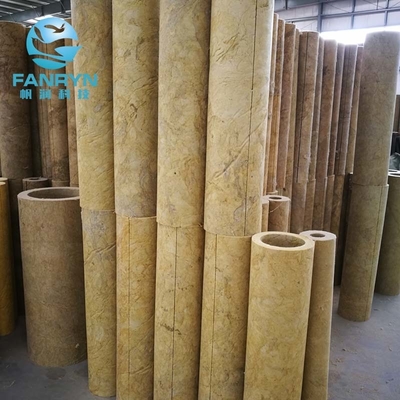

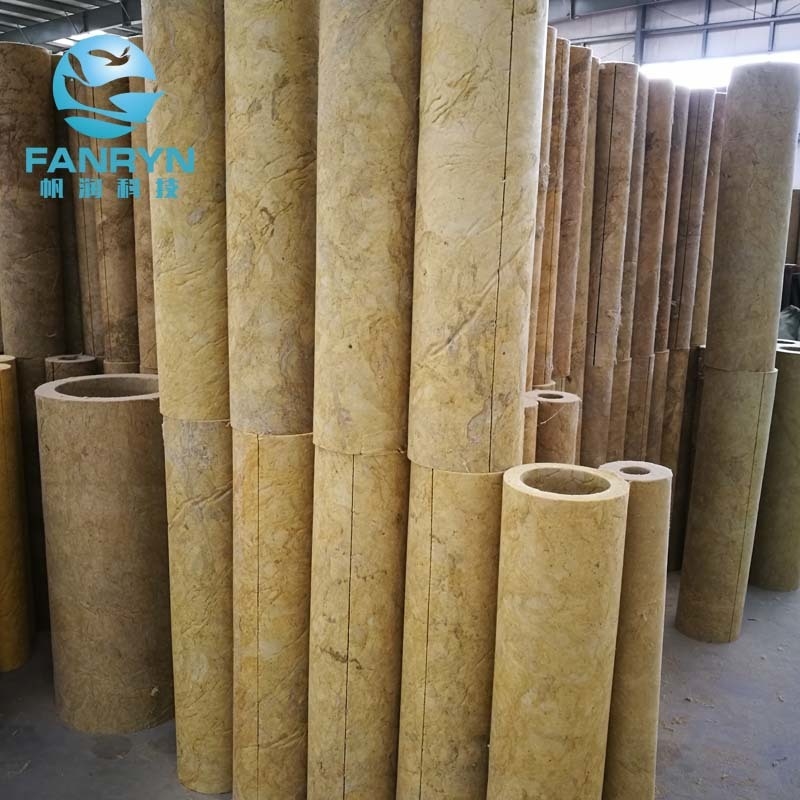

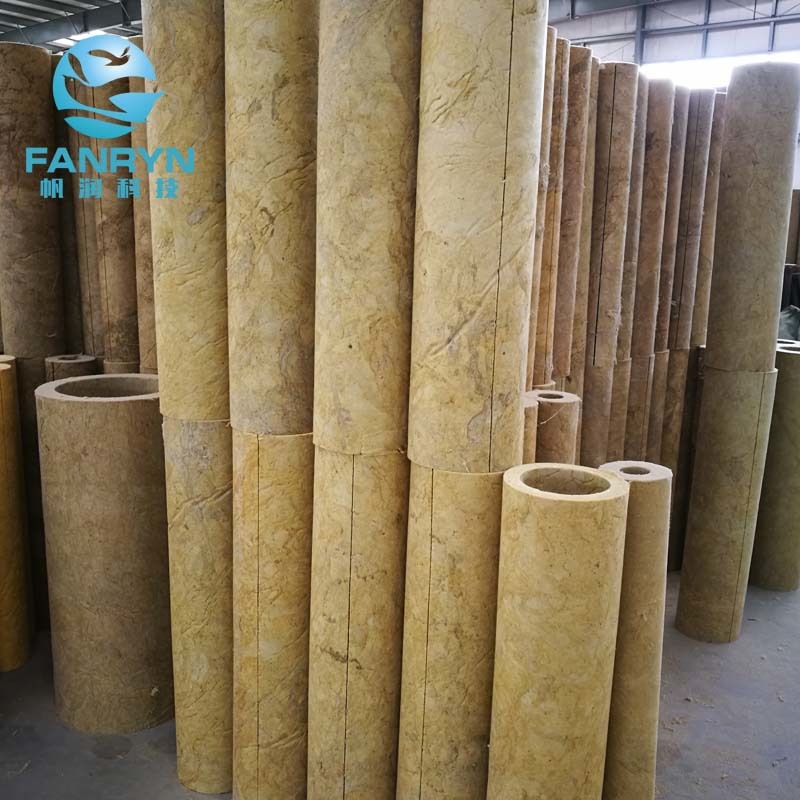

Product introduction of the bare rock wool pipe

FANRYN Rock wool pipe is made from natural rocks such as basalt and limestone. The rocks are melted in a cupola at temperature of >1450 ℃, and the molten lava is fiberized by a spinner. The inorganic fibers are bonded together using a thermosetting resin to form the final product which is cut into suitable sizes for easy handling and installation.

Production details of the rock wool pipe with aluminum foil facing for HVAC

Product parameter of the rock wool pipe with aluminum foil facing for HVAC

|

Properties

|

Specifications

|

Standards

|

|

Density Tolerance

|

±15%

|

GB/T 19686-2005

|

|

Fire Performance

|

Non-Combustible

|

GB/T 5464-1999

|

|

Reaction to fire Class A1

|

GB/T 8624-2006

|

|

Thermal Conductivity

(W/mK, at70±5℃)

|

≤0.044

|

GB/T 10295

|

|

Fiber Diameter

|

7(+/-1)um

|

GB/T 5480. 4

|

|

Shot Content

(shot size>0.25mm)

|

≤12%

|

|

|

Eccentricity of Pipe shell

|

≤5mm

|

|

Product size of the rock wool pipe with aluminum foil facing for HVAC

|

DIA

|

Thickness (mm)

|

|

inch

|

mm

|

25

|

30

|

40

|

50

|

60

|

70

|

80

|

90

|

100

|

120

|

150

|

|

1/2’’

|

22

|

●

|

●

|

|

●

|

|

|

|

|

|

|

|

|

3/4’’

|

27

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

1’’

|

34

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

1-1/4’’

|

43

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

1-1/2’’

|

48

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

2’’

|

60

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

2-1/2’’

|

76

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

3’’

|

89

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

3-1/2’’

|

108

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

4’’

|

114

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

5’’

|

140

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

6’’

|

169

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

8’’

|

219

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

10’’

|

273

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

12’’

|

325

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

14’’

|

356

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

15’’

|

381

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

16’’

|

406

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

18’’

|

456

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

19’’

|

483

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

20’’

|

508

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

22’’

|

558

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

|

24’’

|

610

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

Product feature of the rock wool pipe with aluminum foil facing for HVAC

1.Superior Thermal Insulation

-Effectively reduces heat gain/loss in HVAC ducts, ensuring energy efficiency and consistent temperature control.

2.Integrated Vapor Barrier

-Aluminum foil facing blocks moisture ingress, preventing condensation and maintaining long-term thermal performance.

3.A1 Fire Resistance

-Withstands temperatures exceeding 1000°C, inhibiting fire spread and enhancing building safety compliance.

4.Lightweight & Corrosion-Resistant

-Foil surface provides durable protection without rusting, reducing maintenance needs and extending system lifespan.

5.Noise Reduction

-Absorbs HVAC operational noise (e.g., fan vibrations, airflow sounds), ideal for quiet environments like offices or hospitals.

6.Easy Installation

-Pre-slitted designs and flexible foil wrapping simplify fitting around elbows, valves, and complex duct configurations.

7.Eco-Friendly Material

-Made from recycled volcanic rock and slag, contributing to LEED credits and sustainable building projects.

8.Hygienic Surface

-Non-porous foil resists dust and microbial growth, critical for healthcare and cleanroom applications.

9.Radiant Heat Reflection

-Foil layer reflects external heat radiation, reducing cooling loads in high-temperature environments.

Product application of the rock wool pipe with aluminum foil facing for HVAC

Insulation and fireproof of huge projects like power plant, oil depot and petrochemical works.

Production packing of the rock wool pipe with aluminum foil facing for HVAC

FAQ:

Q1: How to guarantee the quality of the products?

A1: Our experienced QC team will inspect product's quality in every process

Q2: How to pack exported goods?

A2: Plastic bag (Standard Export Packing).

Q3: what is your lead time for one 40HC container order?

A3: Usual 7-10 work days after placing order.

Q4: What is your advantage on rock wool pipe?

A4: Special product with special specification can be made to order.

Q5: About the after-sale service, how to solve the problems occurred of your overseas customer in time?

A5: The warranty of our products is one year. If our products or packing exist quality problem, we will replace or compensate accordingly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!