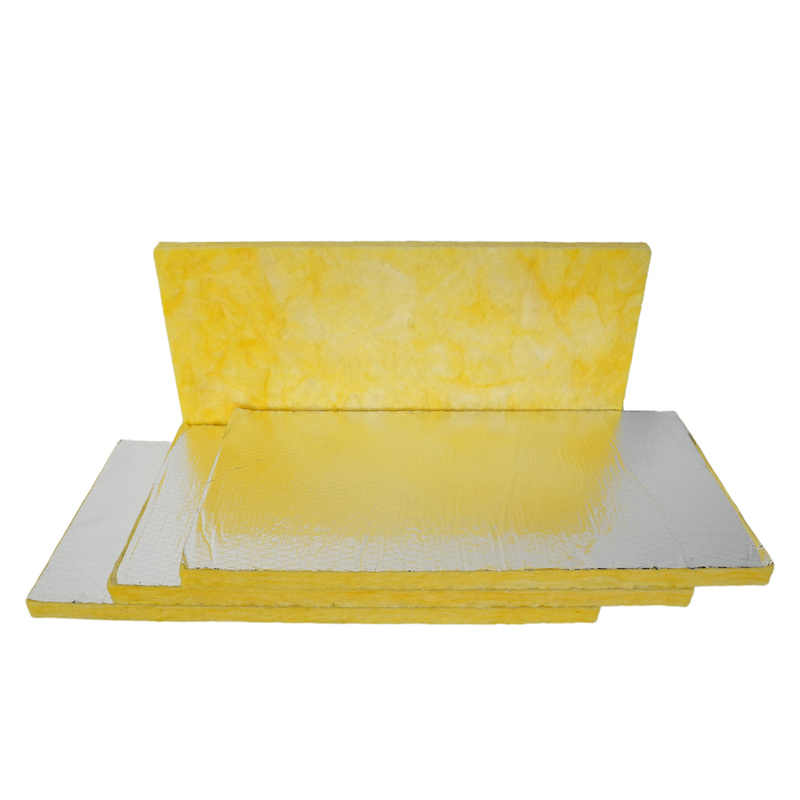

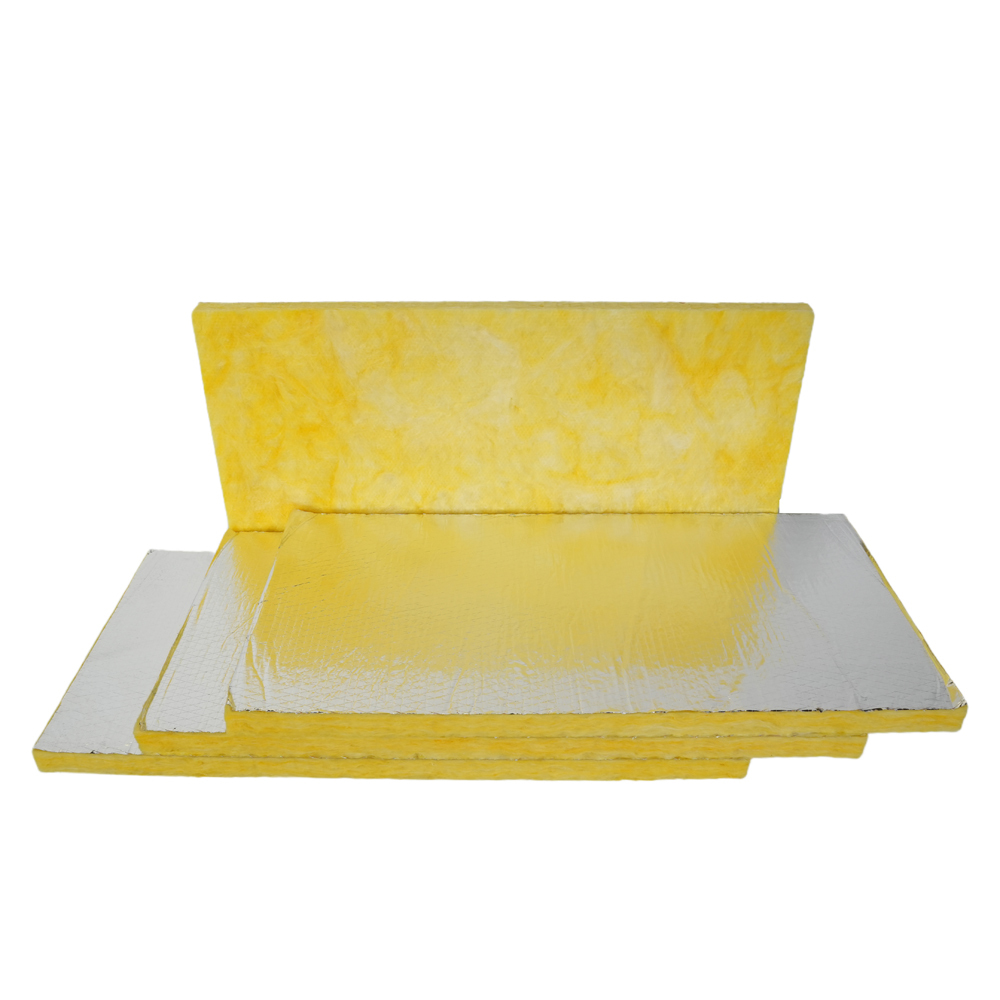

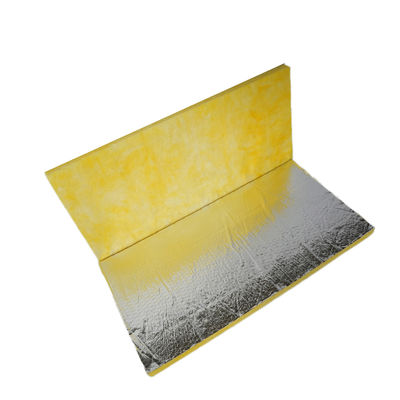

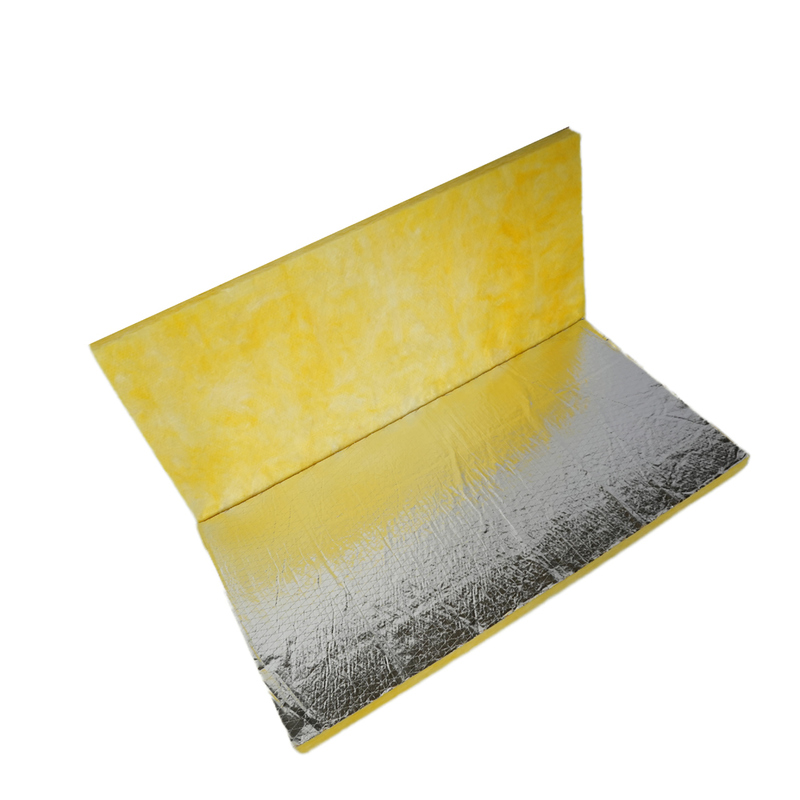

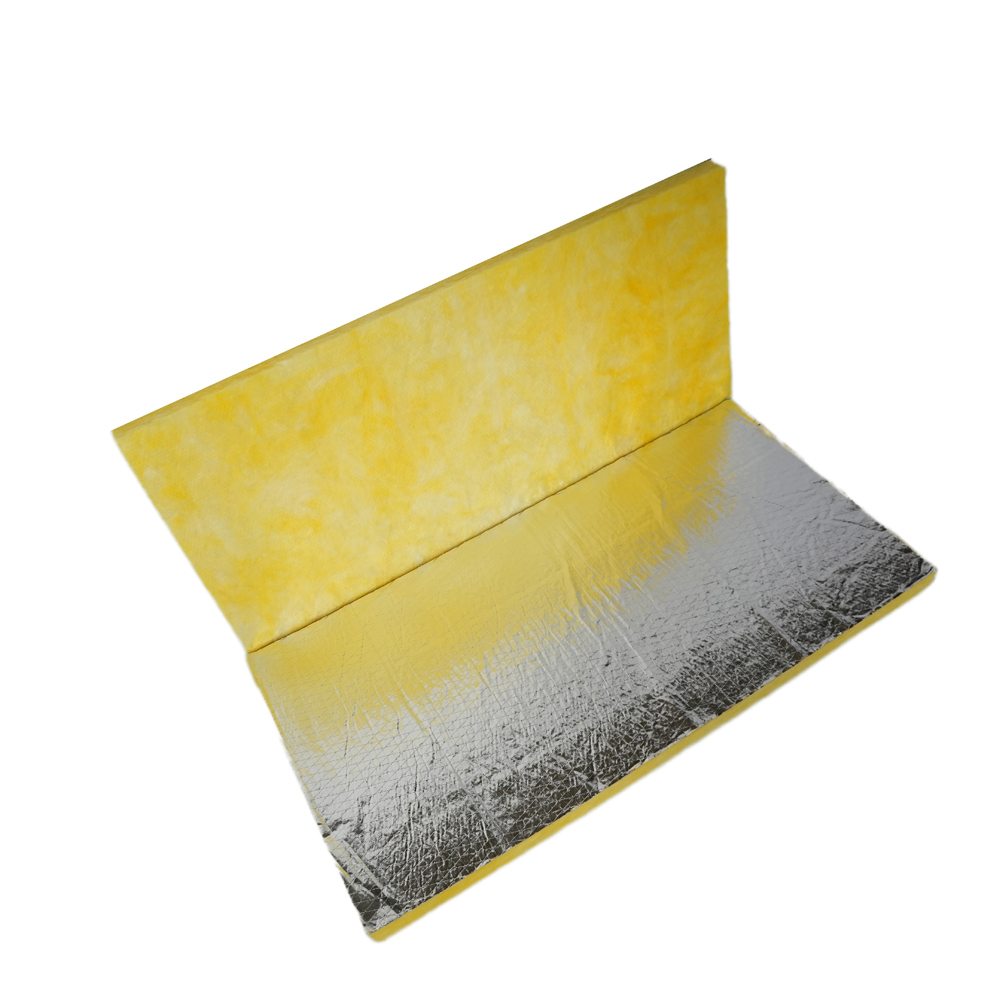

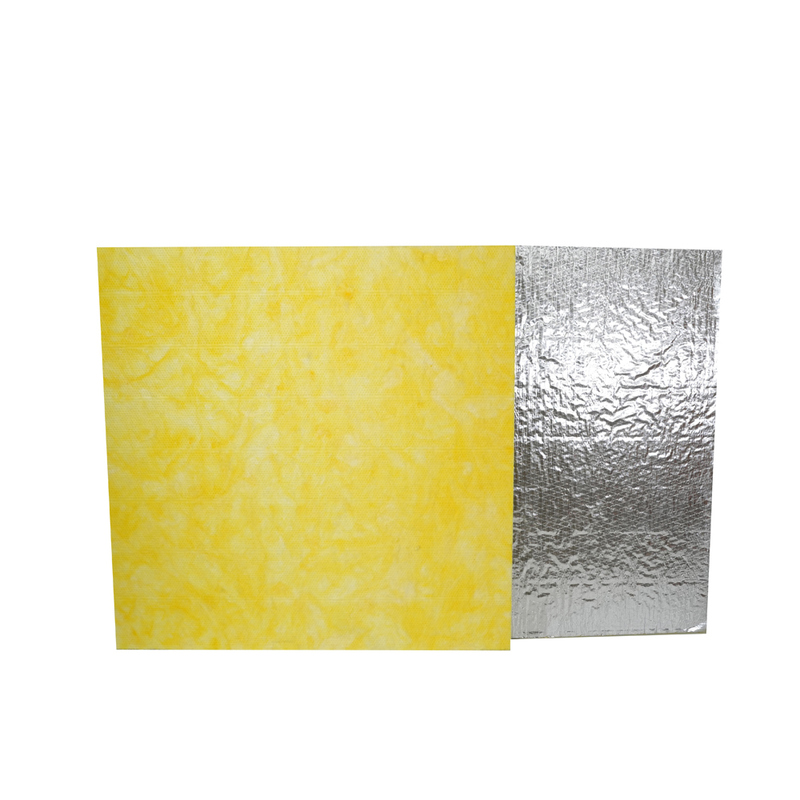

Glass Wool Board

Product introduction of the glass wool board

Designed for industrial noise control, FANRYN Acoustic Glass Wool Board effectively absorbs sound in noisy environments like machine shops and manufacturing facilities. Its porous fiber structure converts sound energy into minimal heat, significantly reducing ambient noise levels and protecting workers' hearing.

Product parameter of the glass wool board

Product size of the glass wool board

Product feature and application of the glass wool board

- High Sound Absorption Coefficient: Excellent performance across a wide frequency range, particularly at 2000Hz.

- Strong Vibration Resistance: Withstands vibrations from heavy machinery without degrading.

- Non-Combustible Safety: Meets strict fire safety standards for industrial settings.

- Robust and Durable: High-density options available for demanding applications.

- Easy Installation: Can be cut to size and fitted into panels, walls, and enclosures.

Typical Applications

- Acoustic panels and enclosures for machinery.

- Wall and ceiling linings in factories and workshops.

- Noise barriers and partitions.

Production details of the glass wool board

Production packing of the glass wool board

The normal packing is plastic bag

OEM is acceptable

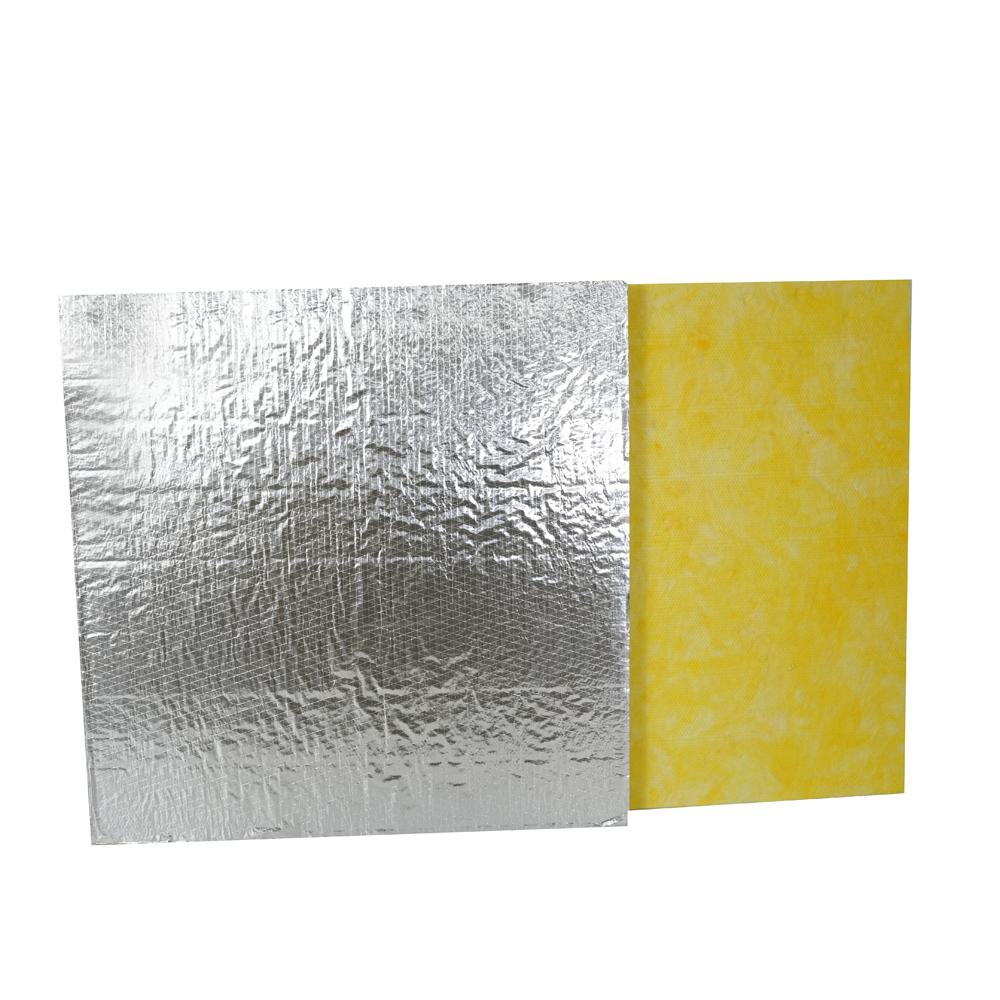

Production Facing of the glass wool board

Foil-Scrim-Kraft Facing

Alum Glass Cloth Facing

Fiberglass Tissue

FAQ:

Q1: How to guarantee the quality of the products?

A1: Our experienced QC team will inspect product's quality in every process

Q2: How to pack exported goods?

A2: Plastic bag (Standard Export Packing).

Q3: what is your lead time for one 40HC container order?

A3: Usual 15-20 work days after placing order

Q4: What is your advantage on glass wool board?

A4: Special size can be made according customer’s requirement.

Q5: About the after-sale service, how to solve the problems occurred of your overseas customer in time?

A5: The warranty of our products is one year. If our products or packing exist quality problem, we will replace or compensate accordingly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!