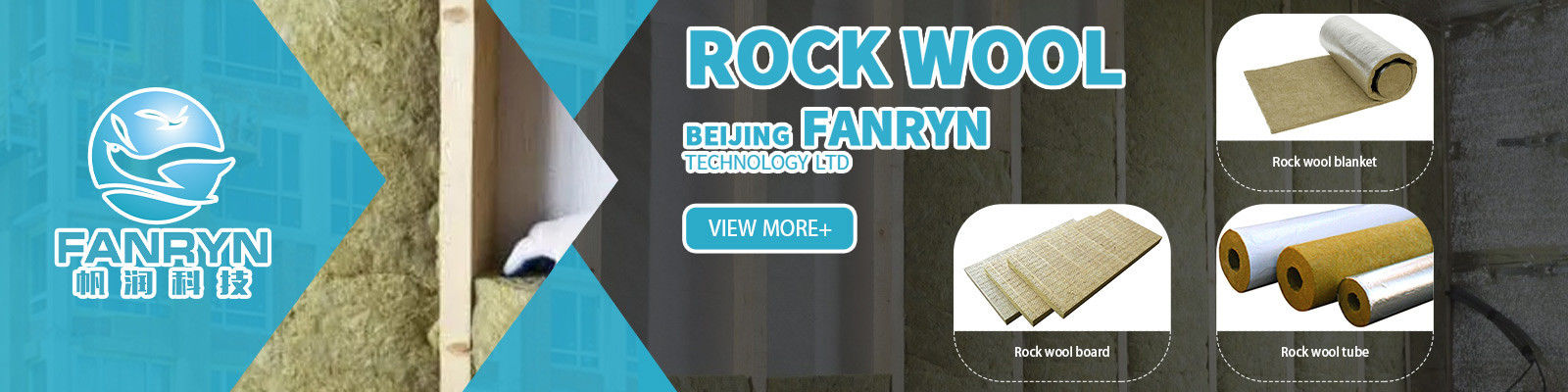

Products Description

Glass wool stands out as a premium, non-combustible insulation solution that delivers exceptional thermal and acoustic performance. In the event of a fire, its inherent safety is proven by emitting zero toxic fumes. This combination of reliable protection and environmental safety makes it an outstandingly sustainable choice for any building project.

Product feature of the glass wool blanket

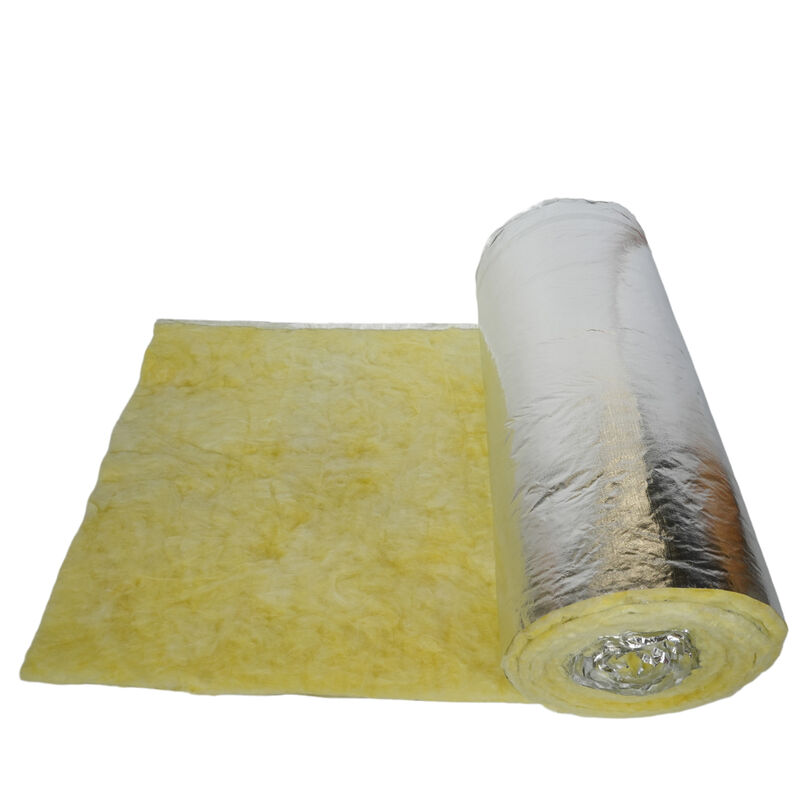

1. Rapid Thickness Recovery – Our glass wool blankets fully rebound to their original, specified thickness within 24 hours of opening the vacuum-sealed packaging.

2. Superior Consistency – Engineered for exceptional uniformity in both thickness and color across the entire product.

3. Excellent Dimensional Stability – Maintains its shape and form over time, resisting sagging or shrinking to ensure long-term performance.

4. Low-Dust Processing – Made with soft, continuous glass fibers that significantly reduce airborne irritation during installation.

Product Specifications

|

Item

|

Unit

|

Index

|

Standard

|

|

Density

|

kg/m3

|

10-100

|

GB/T 5480.3-1985

|

|

Average fiber dia.

|

µm

|

5.5

|

GB/T 5480.4-1985

|

|

Water content

|

%

|

≤1

|

GB/T 3007-1982

|

|

Grade of combustibility

|

|

Non-combustible Grade A

|

GB 8624-1997

|

|

Reshrinking temp

|

℃

|

≥250

|

GB/T 11835-1998

|

|

Thermal conductibility

|

w/m.k

|

0.038-0.06

|

GB/T 10294-1988

|

|

Hydrophobicity

|

%

|

≥98.2

|

GB/T 10299-1988

|

|

Moisture rate

|

%

|

≤5

|

GB/T 16401-1986

|

|

Sound absorption coefficient

|

|

1.03 product reverberation method 24kg/m32000HZ

|

GBJ 47-83

|

|

Slag inclusion content

|

%

|

≤0.3

|

|

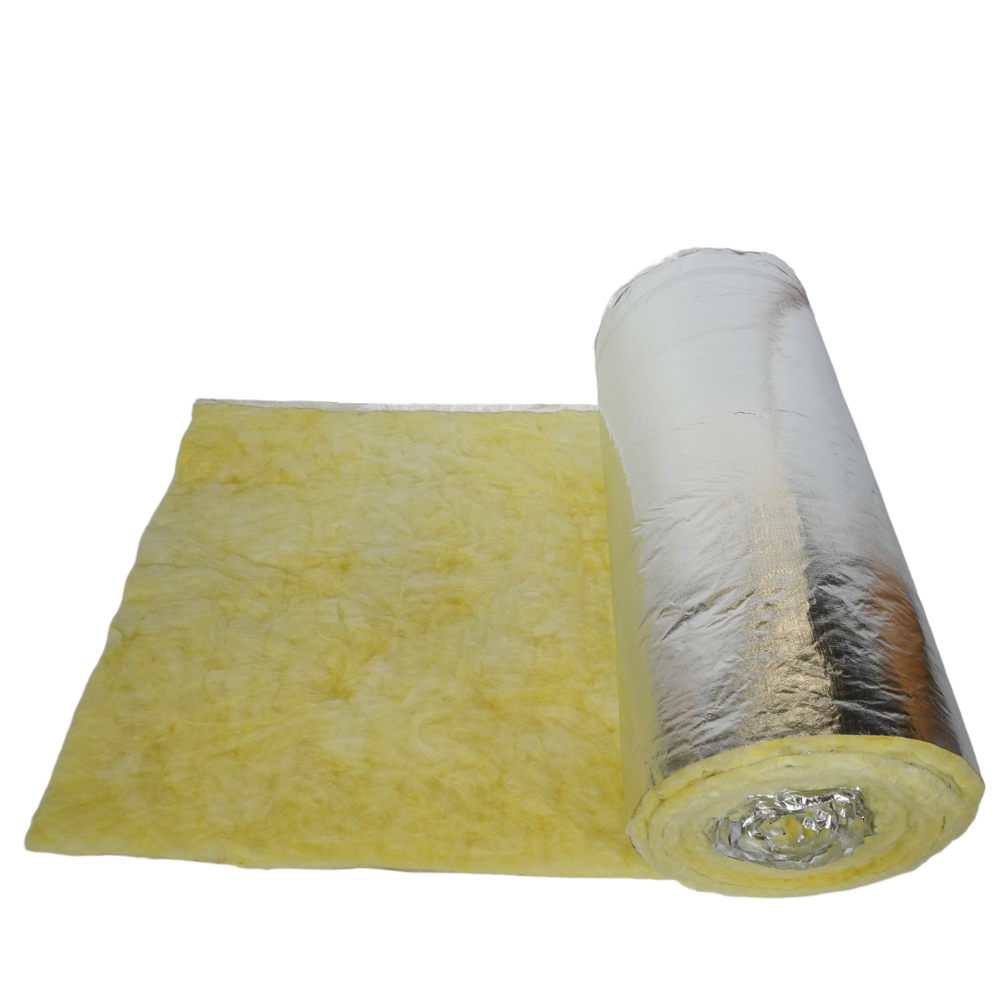

Product size of the glass wool blanket

|

Density(kg/m3)

|

Thickness(m)

|

Length (m)

|

Width (m)

|

Rolls/packing

|

|

10-48

|

0.025-0.2

|

5-30

|

0.6

|

2 rolls

|

|

10-48

|

0.025-0.2

|

5-30

|

1.1

|

1 roll

|

2 rolls overlapping

|

|

10-48

|

0.025-0.2

|

5-30

|

1.15

|

1 roll

|

2 rolls overlapping

|

|

10-48

|

0.025-0.2

|

5-30

|

1.2

|

1 roll

|

2 rolls overlapping

|

|

10-48

|

0.025-0.2

|

5-30

|

1.25

|

1 roll

|

2 rolls overlapping

|

Product application of the glass wool blanket

1. Wall Insulation

2. Structural / Steel Structure Insulation

3. Interior Partition Walls

4. Railway Carriage / Train Compartment Insulation

5. Sound Absorption & Acoustic Isolation

Production Facing For glass wool blanket

Foil-Scrim-Kraft Facing

Alum Glass Cloth Facing

Fiberglass Tissue

Production packing of the glass wool blanket

1. Vacuum plastic bag +woven bag

2. Vacuum plastic bag +woven bag +PE bag

3. Vacuum plastic bag+ PE shrinking bag

4. PE shrinking bag

Note: OEM is acceptable

FAQ:

Q1: How to guarantee the quality of the products?

A1: Our experienced QC team will inspect product's quality in every process

Q2: How to pack exported goods?

A2: Our standard package is Vacuum plastic bag +woven bag (Standard Export Packing).

Q3: What is your lead time for one 40HC container order?

A3: Usual 10-15 work days after placing order.

Q4: What is your advantage on glass wool blanket?

A4: Our glass wool blanket can be freely cut in construction according the shape required.

Q5: About the after-sale service, how to solve the problems occurred of your overseas customer in time?

A5: The warranty of our products is one year. If our products or packing exist quality problem, we will replace or compensate accordingly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!