Products Description

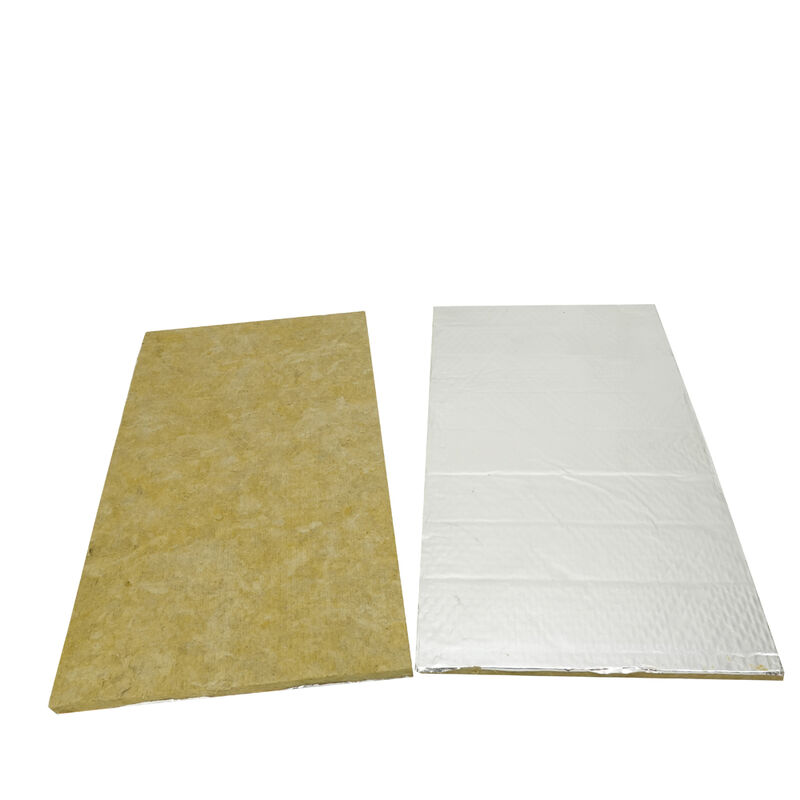

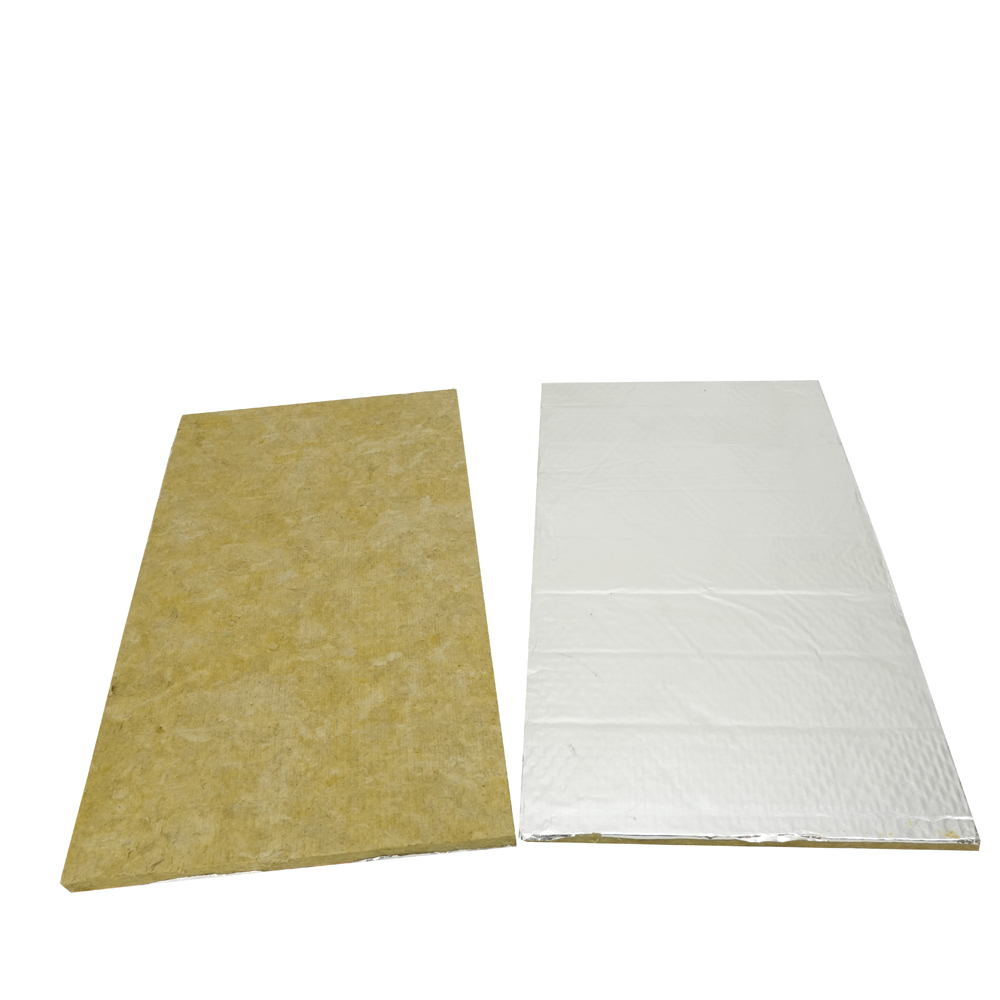

FANRYN Rock Wool Board is produced from naturally sourced volcanic rock, primarily basalt and dolomitic limestone. These raw materials are superheated to a molten state above 1450°C in a cupola furnace, then transformed into fine, inorganic fibers by a high-speed centrifugal spinner. The fibers are bonded with a thermosetting resin to form a dimensionally stable, resilient, and fire-resistant wool substrate.

For enhanced functional performance, the board is factory-laminated on one side with a reinforced, puncture-resistant aluminium foil facing. This facing provides a durable radiant barrier that reflects thermal energy, significantly boosting overall thermal insulation effectiveness. It also acts as an advanced vapour barrier, blocking moisture ingress to maintain the insulation’s performance over time and prevent mould or corrosion. The smooth, robust surface offers improved handling and ease of installation, making it an ideal high-performance solution for HVAC ductwork, roofing assemblies, wall lining systems, and industrial thermal-acoustic applications.

Product feature of the rock wool board

Thermal & Energy Efficiency

The mineral wool matrix and reflective foil work together to significantly reduce heat transfer, cutting energy use for both heating and cooling.

Fire Safety

With an A1 non-combustible rock wool core and foil reinforcement, it ensures high fire resistance without toxic emissions, maintaining stability under extreme heat.

Acoustic Performance

The fibrous structure absorbs noise while the foil adds sound-blocking properties, improving indoor acoustic comfort.

Moisture & Corrosion Resistance

The foil acts as an effective vapour barrier, keeping the core dry to prevent mould and protect against corrosion.

Installation & Durability

Pre-cut panels with a tough foil surface allow for easy handling and installation, ensuring long-term reliability.

Product Specifications

|

Properties

|

Board

|

Standards

|

|

Density Tolerance

|

±10%

|

GB/T 19686-2005

|

|

Fire Performance

|

Non-Combustible

|

GB/T 5464-1999

|

|

Reaction to fire Class A1

|

GB/T 8624-2006

|

|

Thermal Conductivity

(W/mK, at70±5℃)

|

≤0.044

|

GB/T 10295

|

|

Fiber Diameter

|

7(+/-1)um

|

GB/T 5480. 4

|

|

Shot Content

(shot size>0.25mm)

|

≤12%

|

|

|

Moisture Content

|

≤0.5%

|

|

|

Organic Matter Content

|

≤4%

|

|

|

Melting Point

|

>1000℃

|

|

Product size

|

Product

|

Board

|

|

Density (kg/m3)

|

40-200

|

|

Size :L x W (mm)

|

600X1200

|

|

Thickness (mm)

|

30-100

|

Product application

1. Building & Construction

-

External Wall Insulation

-

Roofing Systems

-

Floating Floors

-

Partition Walls

2. Industrial & Pipeline Insulation

3. Sector-Specific Uses

Production Facing

Foil-Scrim-Kraft Facing

Alum Glass Cloth Facing

Fiberglass Tissue

Production packing

1. Vacuum plastic bag

2. PE shrinking bag

Note: OEM is acceptable

FAQ:

Q1: How to guarantee the quality of the products?

A1: Our experienced QC team will inspect product's quality in every process

Q2: How to pack exported goods?

A2: Plastic bag (Standard Export Packing).

Q3: What is your lead time for one 40HCcontainer order?

A3: Usual 15-20 work days after placing order

Q4: What is your advantage on rock wool board?

A4: Special product with special specification can be made to order.

Q5: About the after-sale service, how to solve the problems occurred of your overseas customer in time?

A5: The warranty of our products is one year. If our products or packing exist quality problem, we will replace or compensate accordingly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!